-

Certification

ISO9001/ISO14001/IATF16949

ROHS/UL/REACH/FDA+86 13291521819

Welcome to be our distributor

With the world in the grip of the climate crisis, it has never been more important to focus on green energy solutions. One such solution is wind power, which has become increasingly popular over the past few decades. In fact, wind power is now one of the fastest growing renewable energy technologies worldwide!

Challenges and limitations

Despite the many advantages of wind power generation, there are also some challenges and limitations, such as the instability and volatility of wind power and the dependence on suitable wind energy sources. In addition, energy producers still face significant challenges in terms of wind turbine materials and other infrastructure.

Beginor Polymer material is committed to solving the challenges of manufacturers in the wind energy sector, providing high-quality custom adhesives, sealants and thermal conductivity materials, enabling highly automated and efficient production processes to increase production speed and reduce manufacturing costs. Help shape the future of wind turbine technology and work together for a greener, more sustainable planet.

ELAPLUS Solutions – Connect the infinite possibilities of wind energy

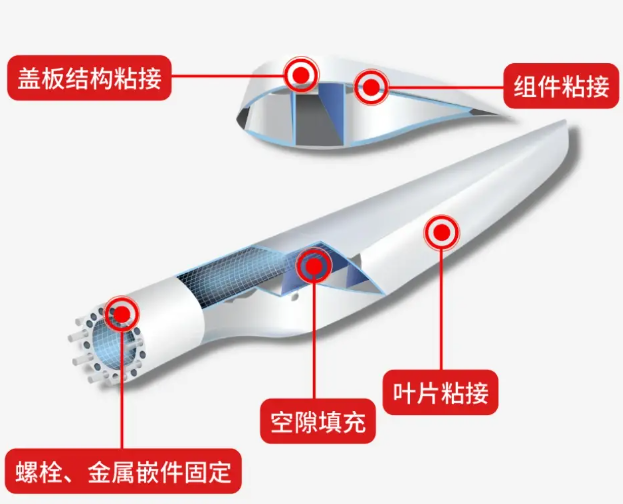

1. Fan blade solutions

During blade assembly, Beginor offers product solutions that can be used to achieve blade bonding. Void filling products include high performance thermal interface composites, our BESIL N9339 and RTV BESIL 9106 products enable component bonding (assembly bonding, cover structure bonding, etc.). It is also suitable for fixing and sealing with bolts, studs and metal inserts.

Glue application

▶ Blade bonding

▶ Gap filling

▶ Component bonding

▶ Fixation with bolts and metal inserts

▶ Bonding of cover plate structure

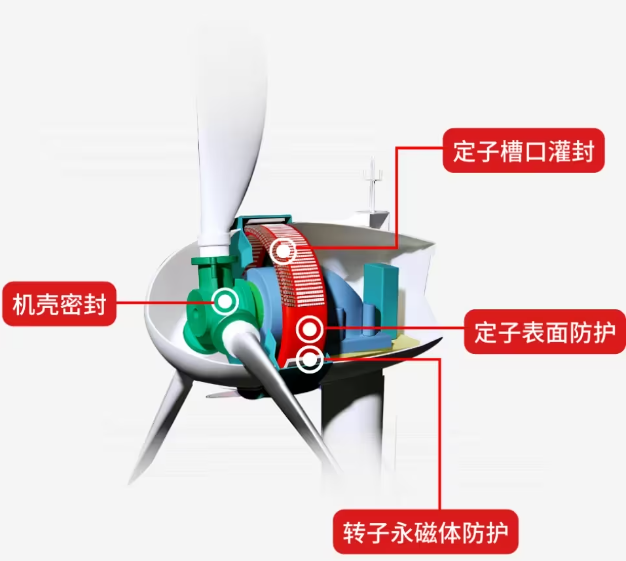

2. Wind turbine solutions

In wind turbines, the most important parts are the stator and rotor. Beginor by using high thermal conductivity adhesive to encapsulate the motor stator as a whole, Beginor can reduce the thermal resistance between the winding and stator core, and improve the thermal conductivity of the insulation system. In the assembly of the generator casing, adhesive can be used for sealing and protection to prevent dust, moisture, etc. from entering the interior of the generator.

Application

▶ Protection of rotor permanent magnets

▶ Potting of stator slots

▶ Surface protection of stator

▶ Sealing of the casing

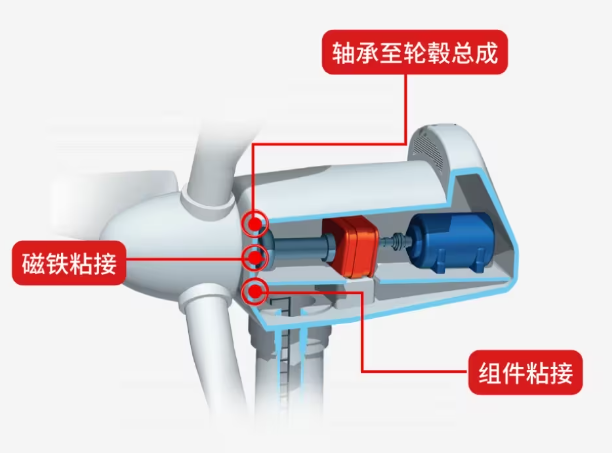

3.Hub and bearing solutions

The engine compartment is the streamlined center of the turbine. During the assembly process of the cabin, Beginor provides high viscosity, scrub resistant, and high/low temperature resistant products for the assembly of bearings, wheels, and gearboxes. In addition, Beginor also has matching solutions for magnet bonding and component bonding, comprehensively maintaining the safety of the wind energy cabin.

Application

▶ Bearing to wheel hub assembly

▶ Magnetic bonding

▶ Component bonding

Recommendation of Beginor Polymer Material

| PUR 5295 ▶ Two component addition-cured silicone rubber ▶ Low hardening shrinkage rate ▶ Excellent high-temperature electrical insulation and stability ▶ Good waterproof and moisture-proof properties ▶ Flame retardant UL V-0 | SIPC 9106 ▶ The adhesive layer is elastic, resistant to scrubbing, and has good adhesion ▶ Resistance to moisture, dirt, and other atmospheric components ▶ Working temperature: -60-260 ℃ ▶ Flame retardant UL94 V-0 |

| SIPC 9102B ▶ Single component fluid, rapid heating and curing ▶ No need for primer to bond a large number of substrates ▶ Working temperature: -60 ℃~+280 ℃ | SIPC 9339 ▶ Excellent chemical resistance and good adhesion ▶ Anti seismic, corona resistant, leakage resistant, and excellent insulation ▶ Stable mechanical and electrical performance between -60 and 200 ℃ |

Tell us your request...

COPYRIGHT ◎ 2023 Elaplus Functional Materials Co. LTD