-

Certification

ISO9001/ISO14001/IATF16949

ROHS/UL/REACH/FDA+86 13291521819

Welcome to be our distributor

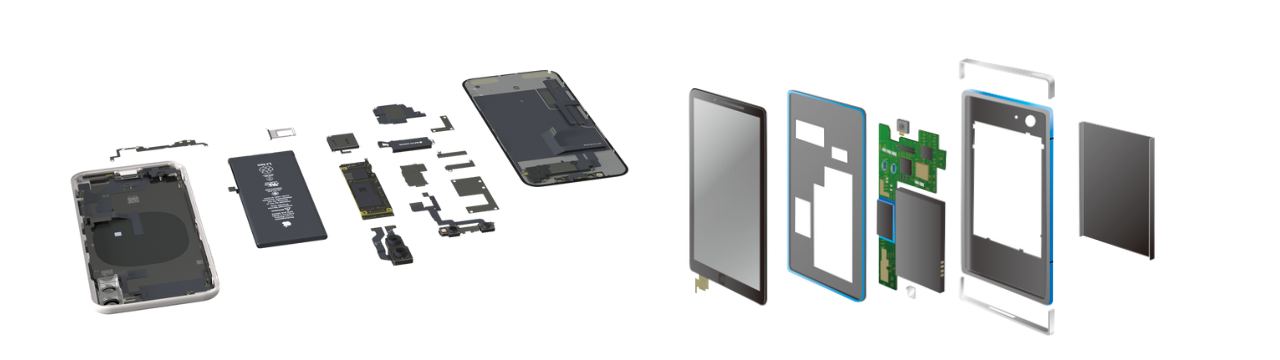

The 5G market is expanding rapidly, and consumer electronics is breaking new innovations. At the mobile phone level, 5G smartphones are currently competing fiercely in technology and product quality between domestic and foreign electronics manufacturers. With the development of smart phones, there will also be some problems:

-Implementation of 5G cell tower and massive MIMO based on high frequency millimeter wave

-As the market demands lighter, thinner and faster devices, the circuits inside the devices become denser

-Thermal management materials have increased requirements for lighter, thinner and better elongation

Managing heat and temperature in these systems is critical to extending service life, especially for components. Beginor Polymer Material is confident to provide customers with any solution in terms of adhesive for smartphones.

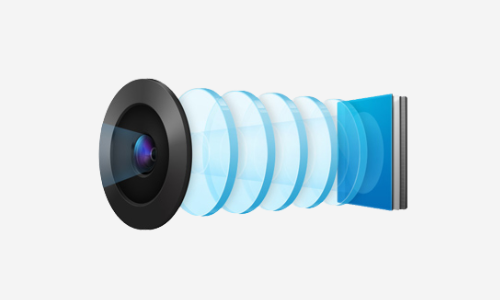

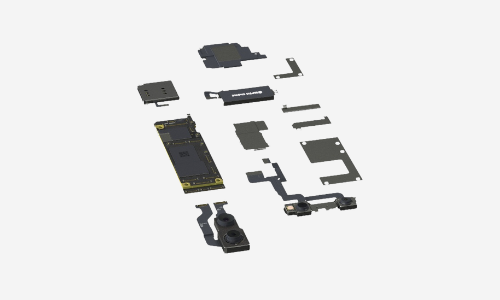

【Camera module bonding】

| EP 6618 Single component low temperature epoxy adhesive ◇ High adhesion ◇ Low absorption of water ◇ It can be used for bonding of various materials ◇ It has good storage stability |

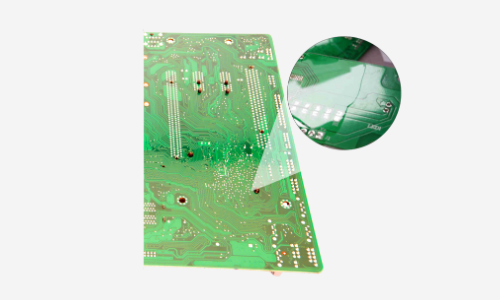

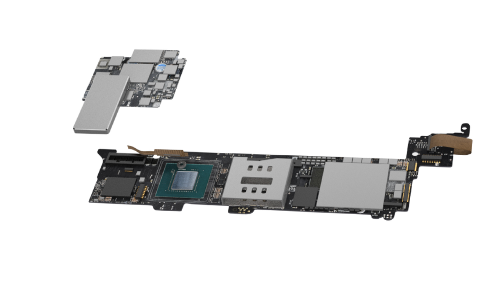

【PCB conformal coating】

| Coating 9007 Silicone conformal coating ◇ One component room temperature silicone ◇ Heat-curable ◇ Medium viscosity, suitable for brush, spray, dip coating a variety of processes ◇ After curing, a transparent elastic protective film with certain hardness and wear resistance is formed ◇ Good adhesion to various circuit boards ◇ Good high and low temperature resistance and flame retardant performance |  |

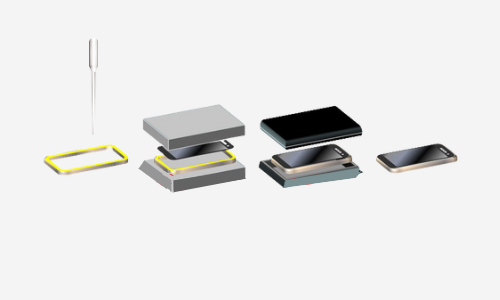

【Touch screen film fit】

| SIPA 8602 Optical Silicone A/B ◇ 1:1 Mixing ratio ◇ High transparency ◇ Low-yellowing ◇ Room temperature curing or heat curing ◇ High toughness and surface viscosity ◇ The process is more optimized |

【Chip bottom fill】

| SIPA 9500 Chip encapsulation gel ◇ Single component direct dispensing without mixing ◇ No need for ultra-low temperature storage ◇ High purity, low ring content very little ◇ Low viscosity, excellent bubble removal property ◇ Can work in a wide range of operating temperatures, -80-230 ℃ |  |

【Bonding fixation for sensor 】

| SIPA 8230A/B Thermal and flame retardant potting compound ◇ Two component addition cured silicone rubber ◇ 1:1Mixing ratio ◇ Low hardening shrinkage ◇ Excellent high temperature electrical insulation and stability ◇ Good water and moisture resistance |

【TYPE C connector】

| SIPC 9102B One-component addition heat-cured silicone gel ◇ Single component fluid, fast heating curing ◇ Passed ROHS REACH UL certification ◇ It is possible to bond more substrates, such as stainless steel, plastic, glass, ceramics, etc., without primer ◇ Excellent toughness and tear resistance ◇ Addition curing system: no curing byproducts |  |

【Speaker bonding】

| PUR 5103 A/B Fast curing polyurethane adhesive ◇ Dispense by machine or mix by hand ◇ Fast curing at room temperature 30mins ◇ Strong adhesion to various substrates ◇ High toughness, high elasticity ◇ Excellent resistance to aging and chemicals |

【Power device heat dissipation】

| TP GEL 35 One component curable thermal mud ◇ Thermal conductivity 1.5 to 4.0 W/m.K Optional ◇ 60℃ / 20 minutes; Or 25℃/ 2~3 days curing ◇ Good temperature resistance ◇ Low compression force application ◇ Automation is possible |  |

| Model | Application | Product type | Product component type | Condition of cure | Application |

| SIPA 8708(#8) | LCD TP fully fit | Silicone | Two-components | Room temperatrue/heat | The touch screen is bonded to the LCD screen |

| SIPA 8602 | LCD TP fully fit | Silicone | Two-components | Room temperature/heat | The touch screen is bonded to the LCD screen |

| SIPC 9102B-1-14 | TYPE C connector | Silicone | One-components | Room temperature | PIN Needle fixation |

| EP 6225FR | Camera module | Epoxy | Two-components | Room temperature/heat | The lens is bonded to the base |

| EP 6112 | Speaker | Epoxy | Two-components | Room temperature/heat | Internal device potting |

| Grease 1112 | Power device heat dissipation | Silicone | One-component | / | Heat dissipation bonding of components |

| Grease 1125 | Power device heat dissipation | Silicone | One-component | / | Heat dissipation bonding of components |

| SIPC 9316 | Power device heat dissipation | Silicone | One-component | Room temperature | Heat dissipation bonding of components |

| Coating 9060 | PCB conformal coating | Silicone | One-component | Room temperature/heat | PCB conformal coating |

| Coating 921L | PCB conformal coating | Silicone | One-component | Room temperature/heat | PCB conformal coating |

Tell us your request...

COPYRIGHT ◎ 2023 Elaplus Functional Materials Co. LTD